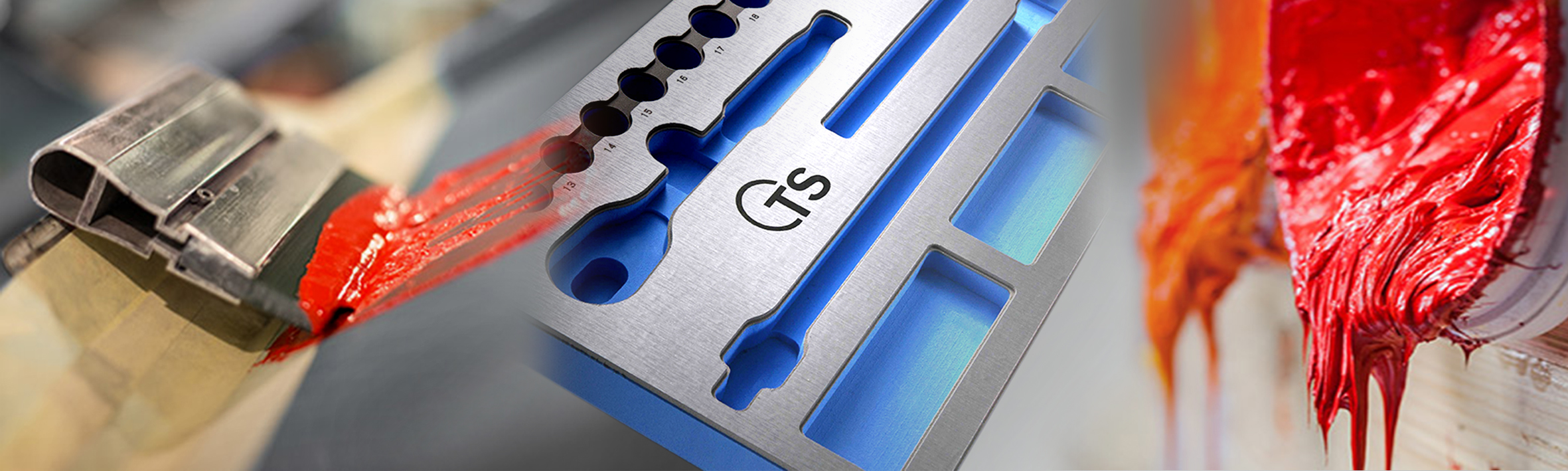

Screen Printing

Screen printing is one of the most rapidly developing and widely adopted methods of silk screen printing. Screen printing is known as universal printing as it has wide applications and the characteristics not seen in other printing methods.

Screen printing is available for any object shape regardless of their size, thickness, hardness, and surface evenness. That is, Screen printing is available for for all of our products.

Recently, with the innovation and improvement in plate materials and printing equipment, screen printing has been transformed from a technique for small-volume large-variety runs to one for large-volume large-variety runs.

Features of Screen Printing:

1. The printing principle is easy to understand. Plate making and operation are simple and diversified

Screen printing is done by forcing ink through hollow hole patterns. It is easy to understand and learn. Various methods for plate making are available.

2. Unlimited substrates

In general, everything except air and water can be printed on. Though the subjects of common printing methods are plain paper or thin slices of materials and their sizes are subject to equipment specifications, screen printing can be applied regardless of surface evenness, not to mention flat surface and thin pieces. Variable printing areas can be used.

3. Outstanding color

The ink thickness of different formats is typically not the same. The ink film of the screen printing ink has the biggest coverage and can print white on backgrounds of a deep color. This can't be done with other formats. Also, the ink film features a stereo texture, creating exceptionally dazzling colors.

4. Screen layout is soft and flexible

The plate has the flexibility and softness of a silk screen, which is ideal for printing on hard objects and curved surfaces.

5. Low printing pressure

The process of screen printing is performed by scraping with a scraper. Therefore, thin materials can be printed on.

The ink thickness of different formats is typically not the same. The ink film of the screen printing ink has the biggest coverage and can print white on backgrounds of a deep color. This can't be done with other formats. Also, the ink film features a stereo texture, creating exceptionally dazzling colors.

4. Screen layout is soft and flexible

The plate has the flexibility and softness of a silk screen, which is ideal for printing on hard objects and curved surfaces.

5. Low printing pressure

The process of screen printing is performed by scraping with a scraper. Therefore, thin materials can be printed on.